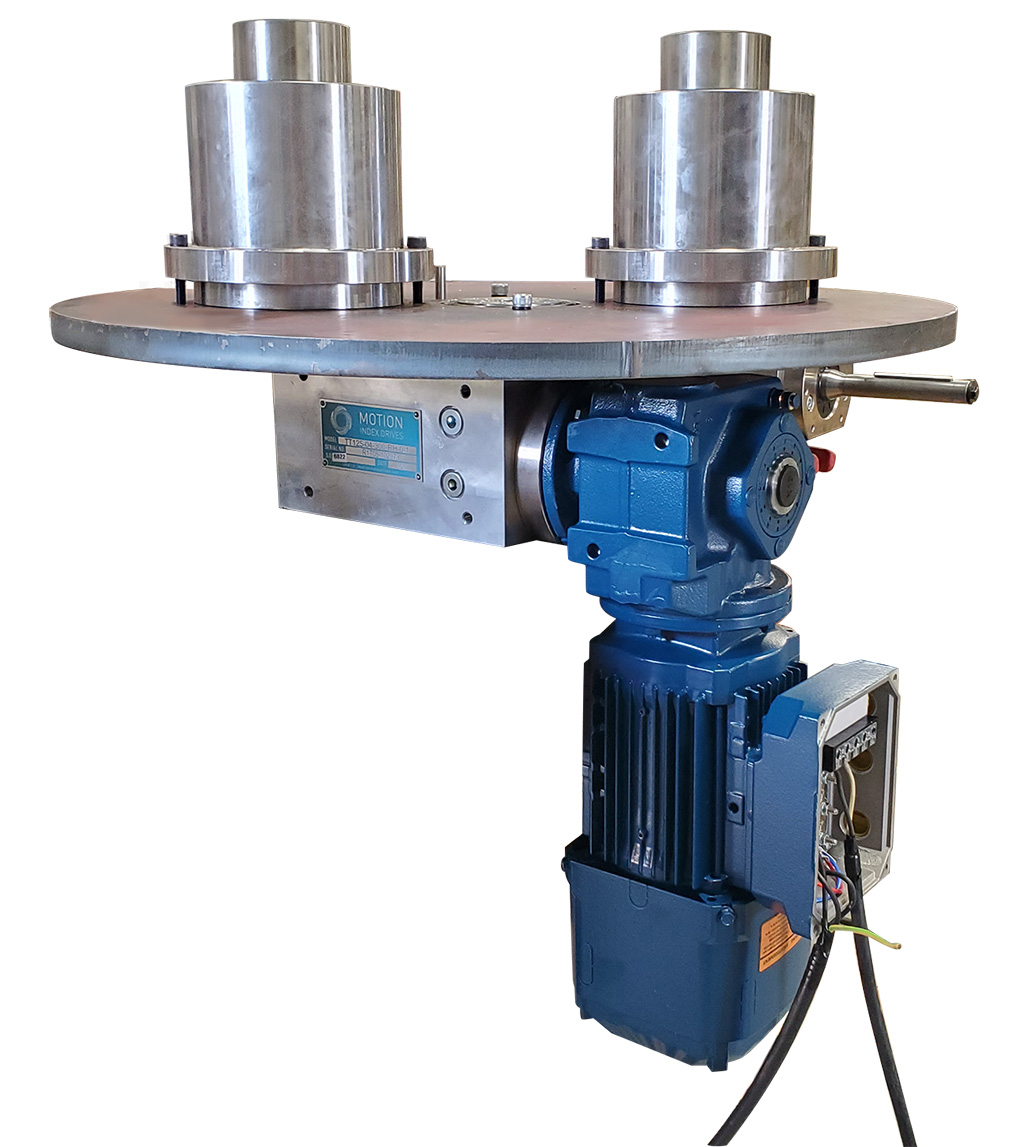

TT125 Indexing Table for Medical Manufacturing

No Comments - Leave a Comment

During this uncertain time, we have been continuing to work on new projects for many different industries. One new project in particular, was a project that was a requirement as a direct result of the Covid-19 pandemic. The requirement for an endless supply of massive quantities of medical grade face masks was met with TT125 Indexing Table for Medical Manufacturing. These masks are used by professionals in the hospital, first responders, and those medically compromised (nursing homes or underlying, pre-existing conditions).

A machine building integrator contacted us and had the requirement for many small machines that produced masks. They need to index 90 degrees in a very short index time, while being cost effective, and being ready to ship in a few weeks. We worked together and through engineering efforts, fit the TT125/4 index drive to this need. The TT125 index drive is a member of our rotary index drives that has an aluminum housing, with steel rotating top dial, tapered roller bearings on the input shaft, and a unique, high capacity central top dial bearing. This unit has a standard accuracy of +/-30 arcseconds, and repeatability of +/-15 arcseconds. We sized a 3 phase AC gearmotor with 24VDC brake to this unit to provide an index time of ~0.5 seconds (mechanical index time) for each 90 degree index motion. Through the many machines being produced, we are hopeful the millions of face masks that will be manufactured on these machines will help to prevent the spread of COVID-19.

Comments

No Comments - Leave a Comment

Translate

Translate