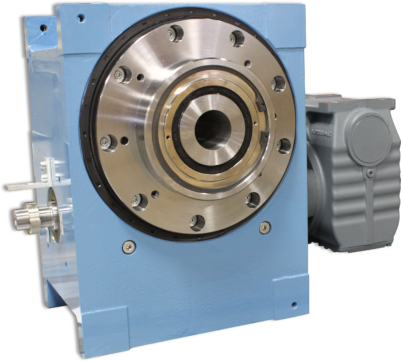

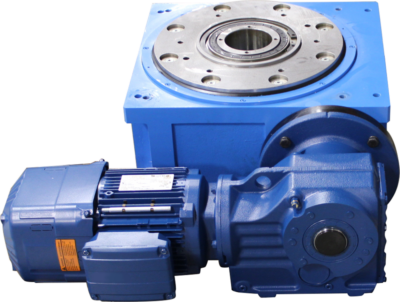

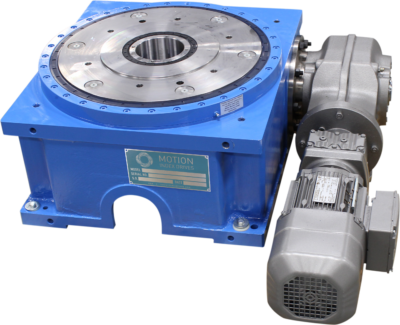

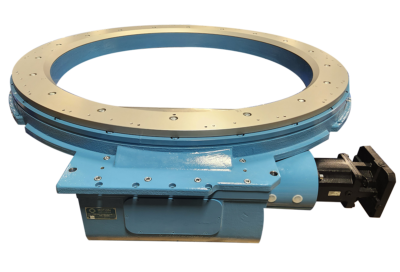

TT Series Rotary Indexer

The TT series Rotary Indexer compliments our line of RT and RTX fixed rotary indexers to allow us to accurately size our customer’s rotary indexing table application. The TT series fills in the gap where our RTX and RT series fixed rotary indexers may be slightly large or too small for a specific application. The Motion Index Drives TT Series fixed rotary indexer ranges from the smaller TT075 up to the TT315. With exception to the TT315, the standard TT Series rotary indexing tables have aluminum housing and flame hardened steel cams. The TT Series is manufactured with a fixed number of stations from 2 stations up to 108 in some models.

Advantages for design engineers and special machine builders

- Mechanical locking in dwell positioning

- Extremely high station to station repeatability

- Zero backlash cam indexing technology/li>

- Suitable for use in any mounting position required

- Dowel holes in housing and in output flange

- Available from a 2 stop up to 108 stops

- Optional synchronization of other mechanical modules

- Easy synchronization of other mechanical devices

Technical benefits for users

- Robust construction for long service lives

- Flame hardened cams and cam followers

- Internal components immersed in oil bath

- Maintenance free

Options available

- Reinforced output flange

- Custom index and dwell angles

- Slip rings

- Clean room ready

- Input shafts lengthened and machined to customer requirements

- More Options

Translate

Translate