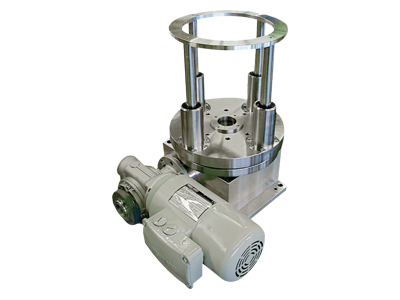

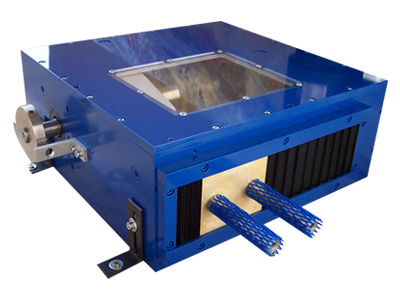

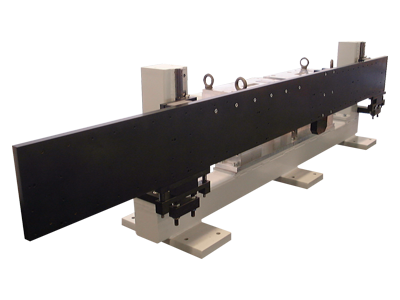

Pick and Place Units

Motion Index Drives Pick and Place Units are customized based on the automation application requirements. Pick and place handling solutions are ideal for high-speed and high-accuracy assembly jobs. A single gear motor controls the dial table and linear lift with synchronized cams, ensuring 100% repeatability and synchronization on every index cycle. With the combination options of cylinder, disk cam, disc groove, globoid, pneumatics and servo technology results in a large variety of pick and place machine solutions.

Advantages for design engineers and special machine builders

- Oscillating index operation capabilities

- Easy synchronization of other mechanical devices

- Compact units offering high torque ratings

- Many different configurations to choose

Technical benefits for users

- Long service lives

- Flame-hardened cams and cam followers

- Compact designs

- Single drive operating both linear and rotary motion

- Accuracies of up to .0009″ (0.023 mm)

- Cam followers last the unit’s entire calculated life

- Completely maintenance free

- Less input power required than leading competitors

- Completely wear-free when used with optional Allen Bradley PLC Controller

Options Available

- Reinforced output flange

- Custom lift and rotate strokes

- Custom index and dwell angles

- User-controlled stations and timing with the MOTION Flex line

- Clean room ready with MEDEX Index Drives

- Extremely high accuracy applications with NANO Indexer Technology

- More Options

Translate

Translate