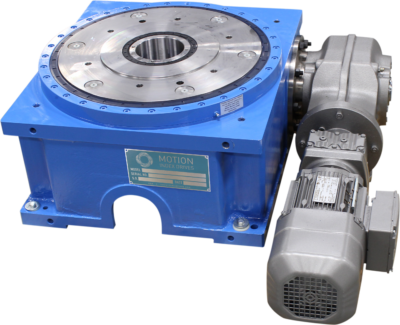

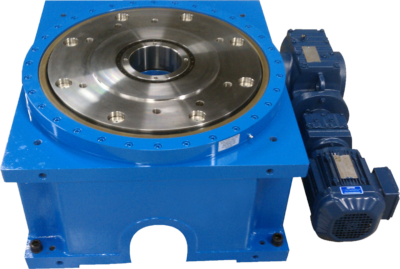

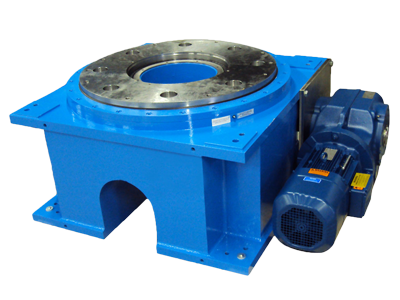

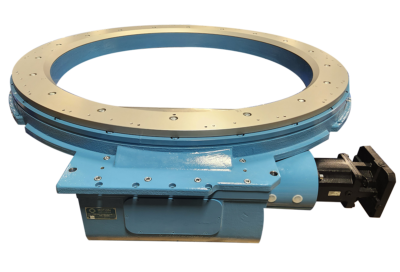

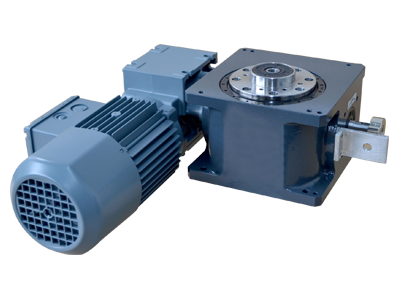

RT Series Fixed Rotary Index Tables

Rotary Index Table

The RT Series Fixed Rotary Index Table is Motion Index Drives’ large series of fixed cam indexers. The RT400 up to the RT900 units are ideal for rotary indexing table applications ranging from 5 feet to over 30 feet in diameter. These fixed cam indexers are offered in a fixed number of stations. They can be operated with a standard AC brake motor and controlled with a simple VFD or motor starter.

The RT Series rotary indexing tables are currently in operation throughout the world in a wide variety of industries.

Advantages

Rotary indexing tables offer multiple advantages to manufacturers, design engineers and special machine builders. Some of these advantages are:

- Zero backlash cam indexing technology

- Mechanical locking on dwell positioning

- Extremely high station-to-station repeatability

- Large center thru-hole to feed pneumatic, electrical and other lines

- Numerous gear ratio possibilities allow for rightsizing indexers

- Vibration-free station-to-station transfers

- Clockwise or counter-clockwise oscillation capability

- Easy synchronization of other mechanical devices

- Ability to be used in any mounting position

Technical Benefits

Automating your manufacturing process leads to several benefits — improved productivity, personnel safety, shorter lead times and faster return on investment, just to name a few. Check out some of the technical benefits of having a high-performing rotary index table:

- Extremely reliable: The fixed rotary index table is built to last for several years. It delivers consistent results, little to no errors and is cost-effective in the long run.

- Power-saving: This index table is designed with high-efficiency mechanical components that require less input power.

- Durable: Cams and followers on the rotary indexing tables are flame-hardened for extreme durability. It is ideal for long mechanical operations daily.

- Self-lubricating: Internal components are immersed in an oil bath, allowing them to self-lubricate and reduce wear and friction. The oil bath also eliminates the need for frequent oiling and greasing, reducing downtime.

- High precision: The rotary index drive works with accuracies of up to ±0.008 mm (0.0003″). This is beneficial for processes that require large volumes of products.

- Maintenance-free: Most RT Series models are maintenance-free, further cutting down costs on repairs and losses from manufacturing delays.

Options Available

Motion Index Drives offers fully customizable rotary index tables. This ensures you get a machine that is most suitable for your manufacturing needs. Some of the additional options available for rotary index tables are:

- Reinforced output flange bearing

- Additional proximity switches or encoders

- Custom index and dwell angles

- Robot pedestals in the center of the indexer

- Powder coating for housing

- Special paint colors

- Dial plates, machine bases, slip rings and air unions

Industry Examples

Aside from manufacturing, the rotary index table also benefits other industries such as:

Choose Motion Index Drives for Your Industrial Automation Needs

Motion Index Drives makes industrial automation accessible to business owners looking to optimize their workflow. We provide cost-effective solutions that help maximize efficiency and improve precision in production.

The RT Series Fixed Rotary Index Table is an application-specific device, meaning it has to be designed for specific operations. Our in-house team is fully capable of customizing your rotary index table according to your unique requirements.

We also offer other automation solutions such as robot transfer units, precision link conveyors, weld positioning systems and other types of rotary index tables. Contact us today for more information on our products and services.

Translate

Translate