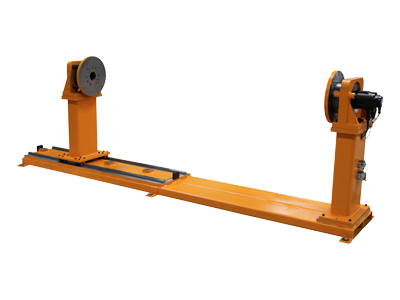

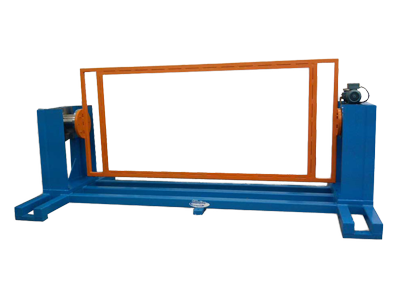

Single Axis Weld Positioning Systems

Motion Index Drives can provide a complete Single Axis Weld Positioner engineered specifically for your needs. The complete Single Axis Positioning System solutions we provide utilize our standard, high-reliability and precise indexing equipment with custom weldments that exceed our customers’ expectations. Our Single Axis Positioning System is utilized in industries ranging from aerospace, heavy construction vehicles, tanker manufacturing, steel industries, passenger train manufacturing, to automobile manufacturing.

Single Axis Weld Positioner Features

- Can accommodate all servo motor and robotic motor brands

- Can operate from standard AC motor single or three phase

- Extremely robust construction to handle heavy loads

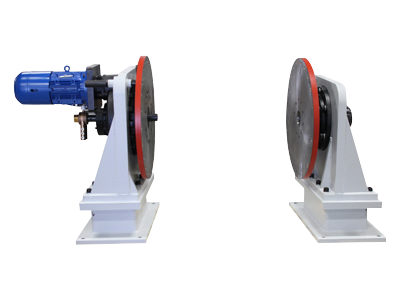

- Headstock (flexible or fixed index drive, with or without drive motor, servo or AC)

- Tailstock (bearing assembly or thru-hole bearing housing)

- Risers (custom height and weldment design)

- Center frame (custom length and weldment design)

- Optional controls drive for motor

- Micarta isolation kits for specific welding applications

- Customer specified paint finish on all stationary components

- Black oxide head and tailstock mounting flanges

Benefits

- Purchase multiple components from one source reducing purchasing management time

- Reduce project management time by utilizing Motion Index Drives to order necessary components

- Minimize your design time by utilizing our standard designs that are readily available

- Minimize assembly time while decreasing your required man hours on projects

- We will mount customer supplied motors and other components to ensure proper functionality and fit

- Minimize shipping and handling costs by purchasing from the source

Translate

Translate