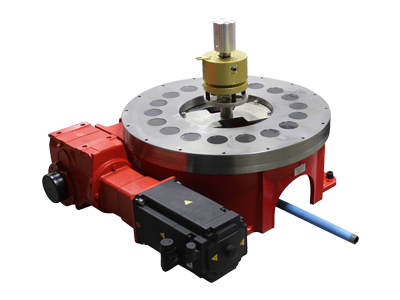

Slip Rings/Rotary Unions

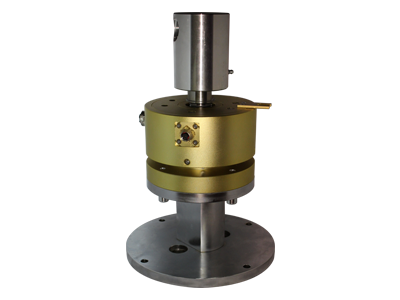

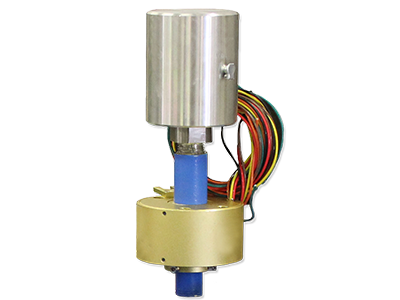

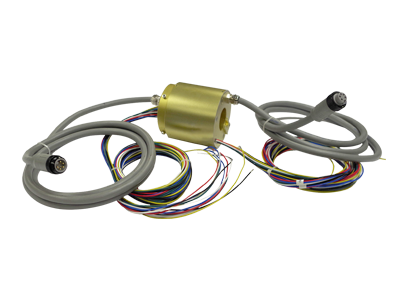

Our MSR series Slip Ring Rotary Union assembly can be manufactured to our customer’s specification. These can be delivered complete with our index drives, to allow for a simpler installation.

Features

- Low and high voltage capabilities from 24 VDC up to 600 VAC 3 phase

- Single circuit up to 96 circuits

- Multiple or single air or fluid ports ranging in size 1/8′” to 1 ½” dia.

- Device Net, Profibus, USB, CanBus and ProfiNet compatible

- Rotary union is capable to transmit air or fluids

- Special connections available for data and electrical

- Custom tail connections with customer specified lengths

Benefits

- Purchase multiple components from one source reducing purchasing management time

- Reduce project management time by utilizing Motion to order necessary components

- Minimize your design time by utilizing our standard designs that are readily available

- Minimize assembly time while decreasing your required man hours on your projects

- We will mount customer supplied motors and other components to ensure proper functionality and fit

- Minimize shipping and handling cost by purchasing from the source

Translate

Translate