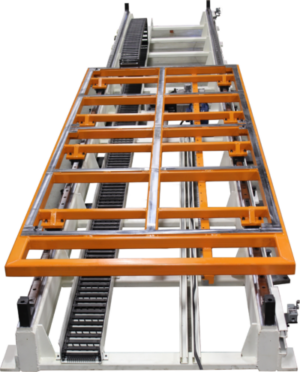

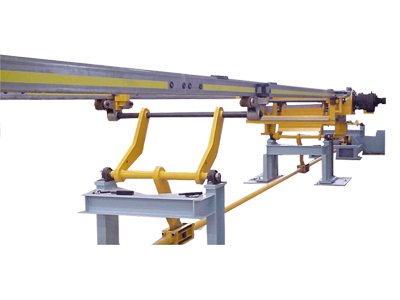

Tool Tray Transfer Systems

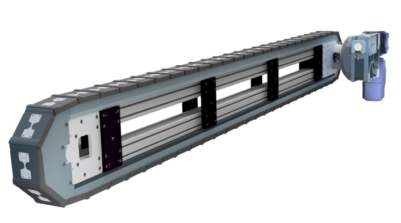

Lazer Arc by Motion Index Drives Tool Tray Transfer Systems combine excellent accuracy using the highest precision guide rails, rack and pinion system and closed loop motor control system with high index speed capability with versatility to meet any automation challenge. Please contact our engineering sales department for further information on our Tool Tray Shuttles – Linear Transfer Systems.

Key Benefits

- Standard accuracy – DIN 6 on gear rack +/-0.0003″/ft

- Rack is hardened and ground – S.F. of rack 4.58:1

- Low backlash Gear Reducer

- Total axis load moving over 100,000 lbs (slide frame and fixture )

- Transfer unit is fabricated and machined welded steel construction

- Transfer carriage manufactured to mount customer tooling tray and fixtures

- Localized pads machined for mounting of tooling tray

- Faster Transfer Times

- Extremely high accuracy through the use of either AC motor with absolute encoder or servo motor control.

Advantages for Design Engineers and Special Machine Builders

- The direct drive gear reducer to gear rack implements higher accuracy and better performance with less components.

- The robust tubular steel construction is designed for easy maintenance and accessibility.

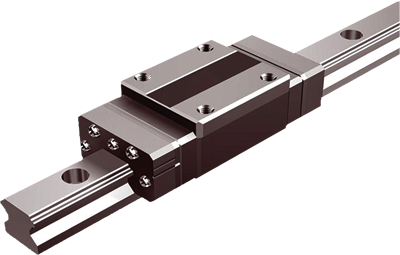

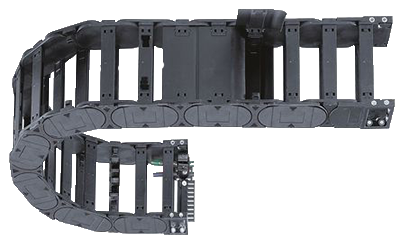

- Over sized linear bearings guide ways enable it to handle more mass as the integrated internal cable carrier reduce floor space consumption.

Tool Tray Shuttles Technical Benefits for Users

- High precision linear rails/guide ways with blocks

- Cable management tray (mounted internally by Motion)

- Hard stops on each end of transfer for over travel

- Special coating to reduce friction and eliminate external lubing

- Installation support by Motion Index Drives at customer facility

Tool Tray Transfer Systems Options Available

- Cable Management System

- Cable tray location

- Carriage size and design

- Motor Brands

- Custom length

Translate

Translate