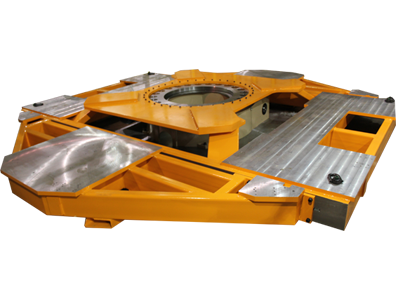

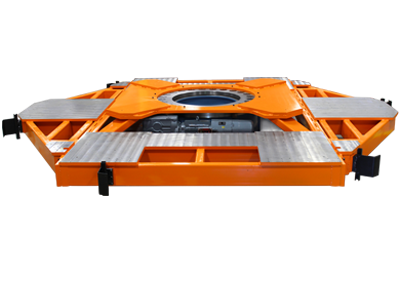

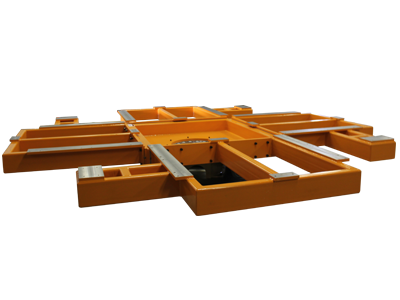

Tooling Frames

Tooling frames and weldments can be manufactured to our customers print. These can be delivered complete with our rotary index drives, to allow for a simpler installation. Weldments can be manufactured to your drawings and can be offered upon receipt of the drawing for quoting.

Features

- Available in extremely low profile designs

- A-Frame, H-Frame welded structures to meet ergonomic load requirements

- FEA studies completed by Motion based on your tooling/fixture loads

- Reduce mass moment of inertia by utilizing our design experience

- Machine enamel, Epoxy or Powder Coating to customers color spec.

- Frames manufactured to allow customer to simply bolt on tooling and fixtures

Benefits

- Purchase multiple components from one source reducing purchasing management time

- Reduce project management time by utilizing Motion to order necessary components

- Minimize your design time by utilizing our standard designs that are readily available

- Minimize assembly time while decreasing your required man hours on your projects

- We will mount customer supplied motors and other components to ensure proper functionality and fit

- Minimize shipping and handling cost by purchasing from the source

Translate

Translate