Clean Room Indexers for Medical Manufacturing

No Comments - Leave a Comment

Cleanrooms are used in automated manufacturing of many different medical tools and devices such as syringes, intravenous and microscopic surgery instruments. Each of these items follow guidelines as to what is acceptable class of clean room that the automated process must be conducted under. Class 100 (ISO 5) for example requires that no more than 3520 particles of 0.5 microns are permitted per m3 of air space.

Contaminants can be generated by product being manufactured, people, tooling, fixtures and equipment moving the products during the automated processes. Motion Index Drive manufactures precision rotary and linear indexing devices that are utilized in clean room environments. Since machinery is a contributor to these particulates that get airborne in clean rooms it is important to minimize this as much as possible. All our indexers are manufactured with components that can be used to meet most classes of clean room requirements.

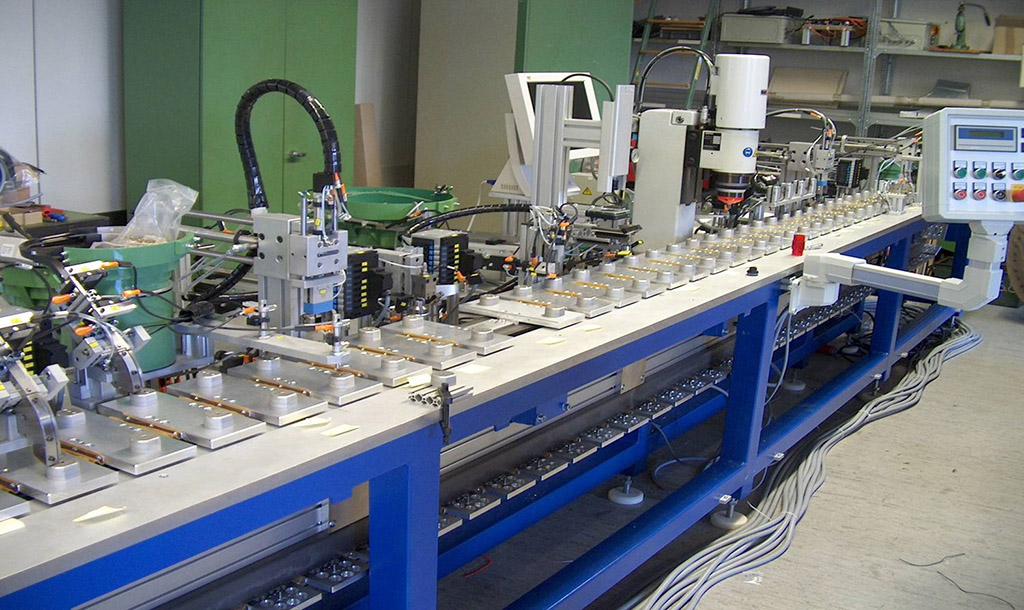

Motion Index Drives has an extensive line of rotary index tables and precision indexing conveyors. Our rotary index tables can be manufactured with custom coatings, special seals, and plating of exposed steel components. The extensive line of rotary index tables is offered in a fixed cam indexing from 2 to 108 positions that can be controlled with motor contactors or simple VFD’s. Our entire line of rotary index tables are also available as fully programmable indexers using servo motors to have infinite positioning possibilities. Our LFA series precision indexing conveyors have five standard size links, LFA050, LFA080, LFA100, LFA125 and LFA150. The LFA precision indexing conveyors can be manufactured in fixed and programmable versions. There is no limit to the overall length that these units can be manufactured. Whether the overall system is 1.0 meter or 20 meter in length, the standard positioning accuracy, from end to end, of our LFA indexing conveyors is +/- 0.07 mm.

Comments

No Comments - Leave a Comment

Translate

Translate