Benefits of Multi-Axis Weld Positioners

No Comments - Leave a Comment

In the age of automation and lean manufacturing, doing more with less is a foundation of most improvement methodologies. Multiple-axis robotic weld positioners expand the possibilities of automation by giving manufacturers the advantage of maximizing throughput while saving on floor space. Multi-axis weld positioners are being implemented in many industries to reduce the footprint required to process and access parts, while minimizing the number of times a part has to be manually moved. This is beneficial for the manipulation of large parts during welding, such as aircraft wings or rail cars, which need to be welded and or painted on multiple sides. With multi-axis robot positioners flipping parts over can be achieved precisely without antiquated and costly cranes and jigs.

Weld positioning systems can be a driven by an aux axis servo motor and controlled by the robot controller or driven by a Gearmotor with brake and encoder.

For larger parts, some manufacturers use handmade, temporary, static solutions or cranes and jigs. While these solutions have worked in the past, in today’s age of automation and lean manufacturing, doing more with less using multi-axis rotary welding positioners is the foundation of most improvement methodologies.

The physics of Multi-Axis Welding Positionersare different from standard rotary tables. Instead of having the load capacities rely on the inertial loading and bearing capacities, a weld positioner is dependent on the static torque output limitations. A welding positioner system that is designed for efficiency will be balanced to move heavy weights at surprising speeds, consistently producing high-quality products.

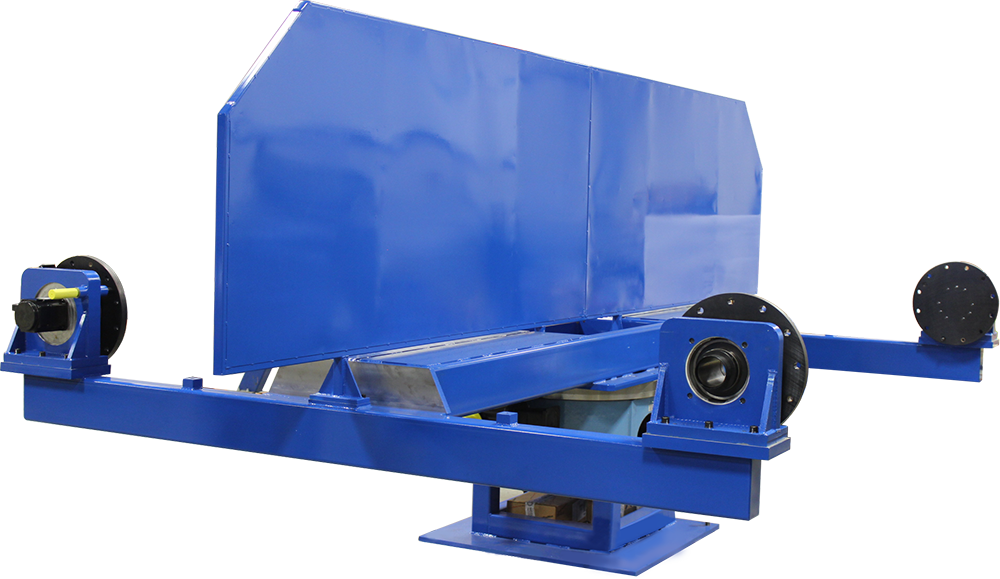

Motion Index Drives’ multi-axis weld positioners provide a superior accuracy, index time, and flexibility to meet the demands of modern automation systems. These complete 3, 4, or 5 Multi-Axis welding positioners are designed and engineered to provide superior performance in demanding industrial automation environments.

Weld positioning systems utilize mechanical drive systems depending on customer requirements. Our high capacity “zero backlash” programmable cam systems create extremely high accuracies and repeatability, while providing mechanical robustness to suit any size application.

All of Motion Index Drives products are built and assembled with the highest precision materials and engineering expertise, and are customized to fit your specific applications. They are offered in complete head and tail stock standard sets and you have the option to purchase a complete trunnion solution that includes heavy duty constructed base frame, HS/TS riser bases, and fixture backbones. A big benefit to integrators is that our systems can adapt to any robot manufacturer their end customers are dictating to use. This minimizes design cost from project to project by not having to use a robot manufacturers dedicated auxiliary axis weld positioner for welding automation.

Comments

No Comments - Leave a Comment

Translate

Translate