Precision Link Conveyors

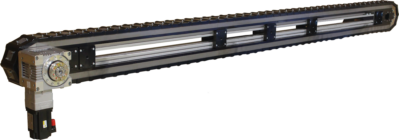

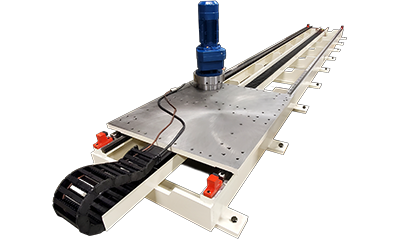

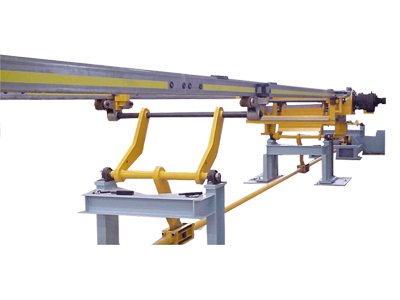

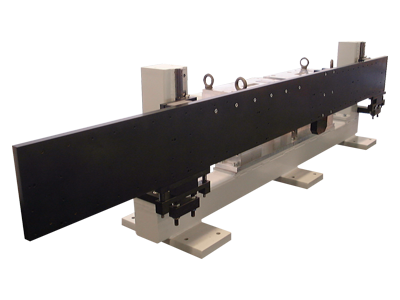

Motion Index Drives’ Precision Link Conveyors combine excellent accuracy and high index speed capability with versatility to meet any automation challenge. Precision link conveyors consist of an index drive, gear reducer and brake motor or manufactured ready to accept a servo motor. Hardened dual-drive sprockets guarantee a backlash-free motion transmission between the drive unit and conveyor chain links. Fixed, hardened chordal compensation cams on both ends of the indexing conveyor maintain a precise tension level in the chain link assembly at all times.

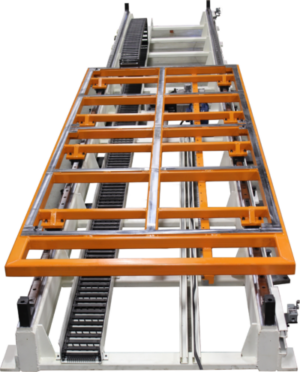

The design of the Precision indexing conveyor is based on a modular assembly chassis concept. The conveyor length between the dual drive sprockets and the fixed chordal compensation cams can be customized according to the required number of workstations. The Motion Index Drives LFA Precision Link Conveyors are offered in many different fixed strokes and completely programmable servo-driven options. Motion Index Drives also specializes in highly complex configuration precision link indexing applications making it the top precision link conveyor manufacturing company catering to your needs.

Please contact our engineering sales department for further information on our Precision Link Index Conveyor Systems.

Key Benefits of Precision Link Conveyors

- Precision Indexing Conveyors utilize very high quality machined aluminum links for the chain which allows for less internal inertia and results in higher loading capabilities, high-speed index times, and smaller indexer required to drive the conveyor

- Hardened and ground steel track for higher rigidity

- Four cam followers engaged on each and every link to steel track, which are sealed requiring no maintenance

- Aluminum extrusion framework to allow for extremely long and very straight lengths, and gives flexibility to mount conveyor and any stationary items to conveyor with virtually no effort versus drilling and tapping

- Center frame can be manufactured to allow for holes, cutouts, or pass throughs

- Extremely high accuracy through the use of either a precision fixed rotary index drive, or the use of a very low backlash gear reducer for servo applications

- Can be manufactured to virtually any length

Advantages for design engineers and special machine builders

- Oscillating index operation capabilities

- Easy synchronization of other mechanical devices

- Can be mounted in a vertical or horizontal configuration

- Length can be changed easily for design or project change

Technical benefits for users

- Proven reliability through many years of service

- Easy synchronization of other mechanical devices

- Lightweight aluminum links

- Maintenance-free indexing mechanism (RT Series rotary table)

- Fast and easy to mount other external stations

- Low maintenance (adjustment of preloading on links done only once a year)

- Guide rails are hardened and fine milled

Options available

- Explosion-proof motors, servo drives and motors for flexibility

- Custom index and dwell angles

- Overload protection devices

- Custom link sizes and linear strokes

- Custom hole patterns on links

- Stainless steel, nickel plating or other special surfaces on select areas

Translate

Translate