Robotic Welding Positioners

Robotic Welding Positioners

Motion Index Drives manufactures robotic welding positioners that offer customers complete flexibility when determining which robot manufacturer to utilize for their project. A big benefit to integrators is that our systems can adapt to any robot manufacturer their end customers are dictating to use. This minimizes design costs from project to project by not having to use a robot manufacturer’s dedicated auxiliary axis weld positioner for welding automation.

Rotary Welding Positioners for Increased Accuracy

Motion Index Drives produces customized solutions for minimal backlash and accurate welding capabilities. We engineer our cam indexers to provide impeccable detail to your welding projects while maintaining speed and project specifications. We are a solutions-based company, so you get customized positioners and indexers that suit your manufacturing needs.

Whether you need fixed rotation or rotation at variable degrees, you get a trunnion system with tailored indexing that responds to your plant’s needs. Add value to your projects and boost your productivity with a customized solution.

Our Weld Positioner Equipment

We have several solutions to increase your manufacturing capabilities for more precision and power. Easily integrate our robotic welding positioners with your current robot for a system powerhouse. Whether you need single-axis, double-axis or headstock/tailstock functionalities, we at Motor Index Drives provide hardened, finish ground indexes for long life with minimal wear and unbeatable accuracy. Choose between several robotic welding positioners.

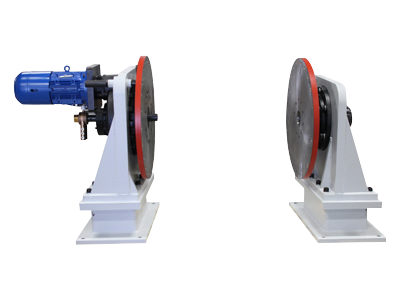

Single-Axis Weld Positioner

Our single-axis positioners are used in various industries and are a cost-competitive solution that drives results. Get highly reliable index capabilities no matter the assignment. The custom weldment designs can exceed your expectations even with heavy loads. You get accurate indexing for incomparable quality.

DR TR Multi-Axis Positioner

For a multi-axis trunnion system that delivers, our DR TR Series offers a zero-backlash turntable for high accuracy and repeatability. The symmetrical design ensures uniformity so that your welding projects do not deviate from project specifications. Let us work with you for an automation solution that indexes objects with precision.

TR Series Headstock/Tailstock Trunnion Set

Motion Index Drives’ headstock/tailstock trunnion positioners are the ideal solution if you want a high-precision system. The superior index modes and hole patterns provide versatility for your manufacturing, while the technical capabilities offer robust longevity for long, reliable service.

Superior Positioners for Welding

We have a complete set of trunnion systems to meet your needs. Being more than just a supplier of high-quality, accurate robotic welding positioners and indexers, we work with you to develop a plan that suits your automation needs.

Our robotic welding positioners offer a lower-cost alternative to welding manipulator applications. The VTMF and RT series trunnion indexing systems have extremely high precision and zero backlash. They are offered in complete head and tail stock standard sets with the option to purchase a complete trunnion solution that includes a heavy-duty constructed base frame, HS/TS riser bases and fixture backbones. Our rotary welding positioners are ideal for rollover applications in many industries, such as aerospace, automotive, defense, construction and mining, alternative energy and railroad transportation manufacturing environments.

Contact Motion Index Drives for More Information

Integrating robotic welding positioners into your system can lower overall costs and increase your floor space, giving you more value for your investment. Our customizable index solutions can elevate your operations and improve your offerings. For fully serviceable, robust rotary welding positioners that increase productivity and decrease downtime, contact Motion Index Drives today at 248-791-9957. You can also request more information using our online form, and we will follow up with you promptly.

Translate

Translate