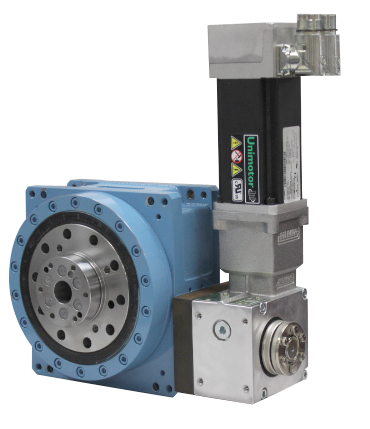

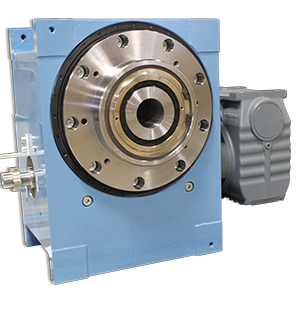

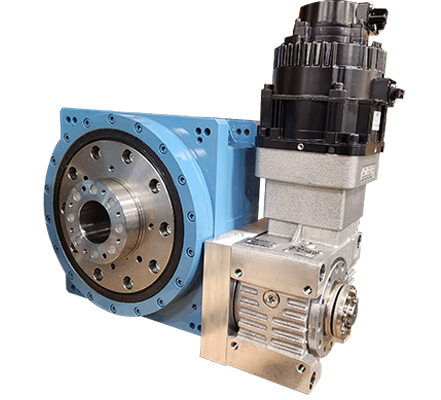

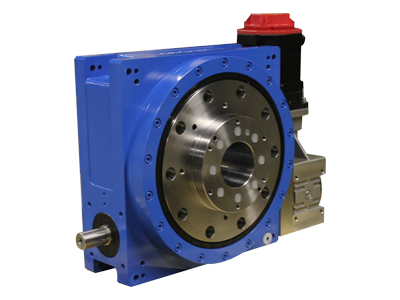

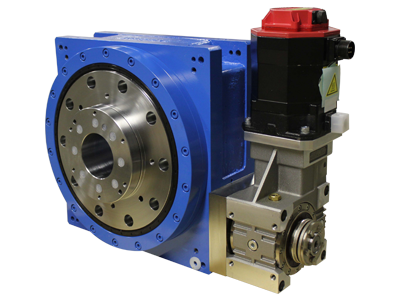

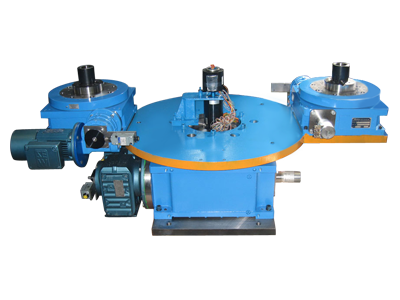

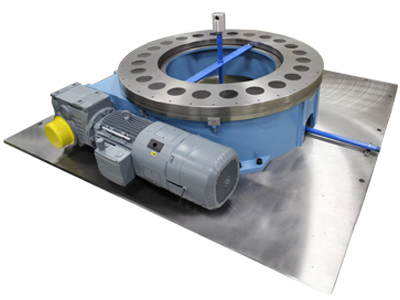

RTF Servo Trunnion

The Motion Index Drives RTF flexible trunnion rotary index drives series encompass our small to medium range of sizes, ranging from our model RTF450 up to our RTF900. Our programmable cam indexing trunnions are offered in three levels of accuracy, ranging from 30 arc seconds down to 5 arc seconds. The RTF programmable cam indexing trunnions can are operated with; AC motors with encoders, servo motors or robot auxiliary axis motors. The number of positions or stops are infinite with our fully programmable cam indexing trunnions. There are always multiple cam followers that are engaged in the cam at all times, which provides a very strong rotary indexer for their relative size. Zero backlash operation is realized in the fully programmable RTF trunnion indexers by using cam and cam follower technology. There is zero backlash on the output flange during operation and while in-position.

Advantages for design engineers and special machine builders

- Large center through holes to run utilities to fixtures

- Most servo motors brands can be mounted

- Can accommodate most robot brands to create an auxiliary axis

- Can be used in any mounting position

- Oscillating index operation capabilities

- Additional tap and dowel holes on all sides to add auxiliary equipment

- Can be used in any mounting position

- Station to station repeatability within single digit arc seconds

Technical benefits for users

- Extremely reliable with long service lives

- High efficiency mechanical components require less input power

- Flame hardened cams and cam followers

- Internal components immersed in oil bath

- Accuracies of up to ±0.008 mm (0.0003″)

- Zero backlash technology via barrel cam and cam follower mechanism

Options available

- Rotary slip rings and air unions

- Safety locking plates for maintenance tasks

- Head and tailstock set

- Custom designed and manufactured risers and tooling backbones

- Rotary grounding devices

- Weld isolation kits

- Linear adjustable bases to allow for different size fixtures

Industry Examples

Solar and Wind Manufacturing

Defense Industry

Aerospace Applications

Translate

Translate