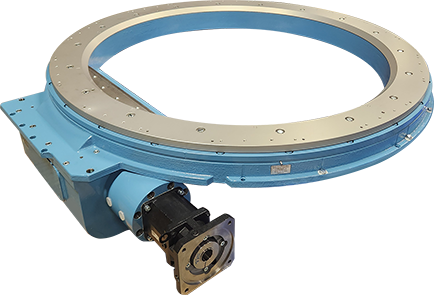

TSR Ring Rotary Index Table

The Motion Index Drives TSR Series Ring Rotary Indexing Table encompasses a range of sizes that offer solutions for many applications. Four different models are available in our standard line: TSR600, TSR1000, TSR1400 and the TSR1900. Our rotary indexing ring tables are ideal for applications that require extremely large, open center accessibility for tooling, robot, and other fixed mounted devices. Rotary ring index drives are not for the average indexing application as in most applications, such a large open center is not required. In these cases, our RT, RTX, TT, or TMF series index drives would be a better solution.

The Flexible Rotary Indexing Ring Table is manufactured with a constant lead cam. This means the angle of rotation can be programmed to be whatever the application requires, and can change by simply altering the program of the motor. The ring indexing drives are driven by a gear reducer and then controlled by an AC motor with encoder OR a servo motor. The positioning is solely based on the encoder position feedback, providing 100% position control through the program of the motor. Fixed TSR series index drives are available.

Advantages for design engineers and special machine builders

- Easy synchronization of other mechanical devices

- Open center for mounting equipment

- Tooling designs can be up to 20′ (6 meters) in diameter

- Oscillation indexing operation capabilities are standard

Technical benefits

- Extremely reliable with long service lives

- Hardened cams and cam followers

- Internal components immersed in oil bath

- Accuracies of up to ±0.023 mm (0.0009″)

- 4-Point contact bearing increases load capacities

- 100% programmable infinite positioning indexing station capability through constant

lead cam

Options Available

- Custom riser base weldments

- Custom top dials

- User-controlled stations and timing with the MOTION Flex line

- Clean room ready with MEDEX Index Drives

- Extremely high accuracy applications with NANO Indexer Technology

- More Options

Related Products

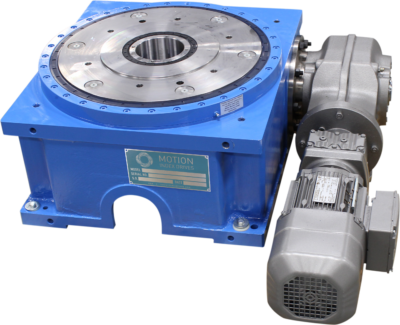

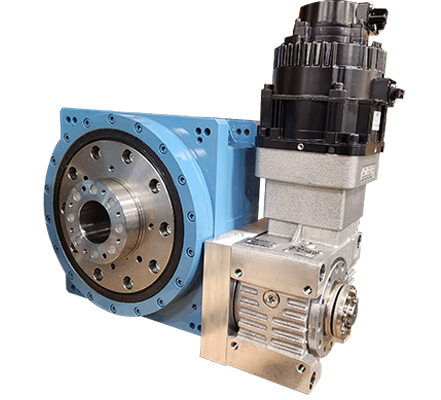

RT Series Fixed Rotary ... >

RTF Series Servo Rotary... >

Trunnion Index Drives >

Translate

Translate