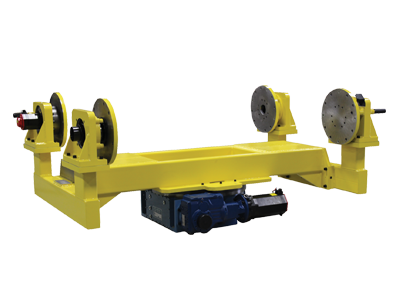

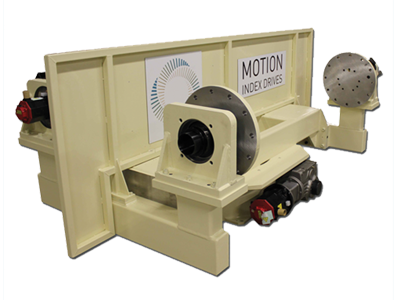

DR TR Multi-Axis Weld Positioner

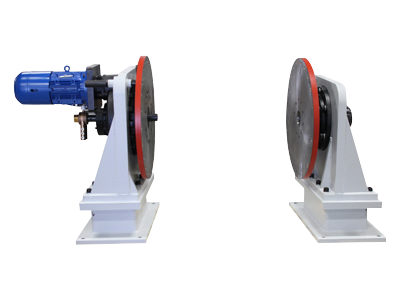

The Motion Index Drives DR-TR Series dual trunnion weld positioning system utilizes our high capacity “zero backlash” TMF rotary turntable for the 180° exchange which creates accuracies of 9 arc seconds and repeatability of 2-3 arc seconds. The unrivaled accuracy of the TMF indexer eliminates the need of “Shot Pin/Wedge” devices that are required from other manufacturers for high accuracy on their 3-axis (H-Frame Positioner) dual trunnion welding positioner systems. Utilizing MID’s TR Series servo gear head with high torque capacity, for the dual trunnion headstocks, allows for a 2 second 180° rotation on a load of up to 4000lbs per side and 3 meters between faceplates. The TR Series tailstock features a large 90mm through hole for customers to run utilities to their tooling and fixtures. The DR-TR Series multi-axis welding positioner system is constructed with strength and reliability in mind. The robust design and components of our Dual Trunnion Weld Positioning System ensures this device will maintain precision in intense factory settings.

Advantages for design engineers and special machine builders

- Flame hardened cams

- Multiple oversized cam followers engaged with cam at all times

- Programmable rotation angles of both base rotary movement and dual trunnions

- Fixed central guarding between both trunnion sides

Key Benefits of Dual Trunnion Weld Positioning System

- Large center through hole to run utilities to tooling and fixtures

- Easy access to pipe and wire all components

- Standard models available to begin design immediately

- Large range of standard sizes for many different applications

Technical benefits for users

- Extremely reliable with long service lives

- Accuracies of up to 9 arc seconds

- Ergonomically friendly position height

- Fully maintainable with all wear components capable of being serviced at facility

- Very low maintenance components

Weld positioning system options available

- 9 standard models

- Custom paint colors

- Custom central guarding

- Custom frame width available

- Can utilize any servo brand

- More Options

Translate

Translate